Beryllium reactions: Beryllium is placed in copper(II) chloride crystals and wet with a few drops of water. The reaction is extremely violent, so the solution is diluted. The reaction remains very violent. Large quantities of copper are produced and a dirty solution is left behind. This solution is neutralized with ammonia to form an extremely gelatinous precipitate containing some occluded copper. Here are the initial reactants, the reaction (steam obscures the view), the precipitate under flash lighting and fluorescent lighting, and the copper residue.

Bismuth dissolution: Bismuth is dissolving in a 2:1 mixture of hydrogen peroxide and hydrochloric acid. The resulting bismuth piece lacks the original iridescent oxide coloration and is pitted and corroded. Addition of an excess of ascorbic acid followed by tincture of iodine formed no precipitate, only a light yellow solution. Therefore, it must be determined that I have failed to produce a precipitate of bismuth iodide, just like I did with tin iodide outside of my school lab. The resulting bismuth solution is diluted with water. Bismuth oxychloride precipitates. Left picture: Bismuth solution with bismuth metal in bottom. Right: Bismuth(III) chloride and water, hydrolyzed.

Iodine disproportionation and reactions: A piece of calcium is placed in tincture of iodine. The calcium vigorously dissolves, producing a large amount of heat. As the solution gets cloudy from the calcium hydroxide, the red-brown coloration of the triiodide ion disappears, replaced by the colorless iodide and iodate: 6 OH- + 3 I3- à 3 H2O + IO3-+ 8 I- As evidenced by this reaction, this is a highly inefficient way of producing calcium iodate, but the reaction itself is interesting for experimental purposes. When acetic acid was added, the solution became a shade yellow again, showing that some of the reverse reaction occurred, though in very small amounts. Addition of sodium hypochlorite did not cause any crystallization of calcium iodate or periodate, probably because the solution is mostly all water.

Bismuth dissolution: The remaining bismuth chunk from the above experiment is redissolved in the same solution. I then took some of the bismuth solution and placed a piece of zinc in it. The zinc immediately turned black, and the black coating of bismuth began thickening. An air bubble trapped against the zinc created a hole in the black coating, showing how thick it is. Some hydrogen was produced, and some of the bismuth hydrolyzed in the solution. Another portion of the bismuth solution was reacted with the previously produced calcium iodide-iodate-hydroxide mixture. Residual hydrogen peroxide, as well as the acidity of the solution, formed orange-brown triiodide, but when reduced with ascorbic acid, a yellow complex remained. This yellow complex turned white when diluted with water, showing that it is a bismuth iodide complex. Pictures are 1-4: bismuth reduction by zinc, 5: turbid bismuth(III) chloride solution, 6: bismuth iodo complex.

Iodine reactions: Tincture of iodine is acidified with hydrochloric acid and reacted with bleach. Some iodine forms initially, which reacts with nascent chlorine from bleach + hydrochloric acid to form iodine monochloride solution, which is yellow. Sodium bicarbonate is added, and iodine precipitates, as well as sodium chloride (due to the high concentration of ions in the solution). The iodine is filtered and dried a little. Some of the specks of iodine were placed in a vial and then placed in hot tap water. The purple color of iodine vapor formed, barely visible at that temperature. Then the vial is placed in boiling water. Almost all of the tiny iodine fleck evaporates, leaving the impurities behind and producing a bright purple coloration. When cooled, tiny iodine crystals are deposited on the walls of the vial. 1: Iodine crystals 2: Iodine vapor at 40 C 3: Iodine, deposited crystals.

Tantalum cleaning: I placed my tantalum chunk in hydrochloric acid in a vial and placed the vial in a boiling water bath .Most all of the manganese dioxide left dissolved and the solution was green because of dissolved chlorine gas. It reeked when I poured it down the drain.

Bismuth hydrolysis: Bismuth oxy compounds at pH 2 or 3 are white, while those at higher pH are light yellow.

Bismuth oxide production: The bismuth oxychloride is filtered and dried.

Silver dissolution: Silver is anodized and then placed in a 1:1 mixture of 3% hydrogen peroxide and 5% acetic acid.

Bismuth oxide reactions: Bismuth oxide is heated on aluminium foil. It melts and then rapidly contracts. When the resulting sphere is broken open, there is a small bead of bismuth metal along with a white fused oxide and a yellowish oxide. The molten liquid was splashed onto a cold surface to form a yellow bead that has a small bead of bismuth metal poking through one end. Since the melting point of bismuth trioxide is around 700 C, it easily melted in this hot flame. Some evidently reacted with either the iron wire loop or the aluminium foil to form the metal oxide and bismuth metal. The yellow surface dulled overnight; it is only barely visible in the second picture.

Silver reduction: Manganese dioxide is placed in the silver acetate solution. An abundance of hydrogen peroxide is decomposed. A copper wire is added. It gets coated with a thin layer of silver but no further reaction occurs. The solution turns green as the copper dissolves. Here is the copper wire at its initial and final silver level.

Further waiting produces a small amount of purplish micro-particulate silver, which collected on the bottom of the vial. Swishing around the precipitate produces a purplish suspension.

Reaction of ascorbic acid with some of the silver acetate solution forms the same purplish coloration without producing actual flecks of silver metal. The video that was taken was deleted because of its unimpressiveness.

The original silver acetate shows a little signs of disappearance as well; it is a little bluish, indicating some dispersed silver. Some of the silver acetate solution is placed in the calcium iodide/iodate mixture from a previous experiment. The residual hydrogen peroxide and acidity oxidized some of the iodide to triiodide again, leaving a yellow precipitate and brown solution. When ascorbic acid is placed in the solution, the triiodide is reduced to iodide, the hydrogen peroxide is reduced to water, and any residual iodate is reduced to iodide. This leaving no excess ascorbic acid to reduce the silver iodide, a yellow precipitate formed of silver iodide.

The remainder of the silver acetate solution is neutralized with sodium bicarbonate to form silver carbonate. Several reactions are occurring: baking soda is neutralizing vinegar, silver salts are catalytically decomposing hydrogen peroxide solution, sodium bicarbonate is precipitating silver bicarbonate, and silver bicarbonate is decomposing to silver carbonate and carbon dioxide gas. The resulting precipitate is pure white, showing no contamination of silver oxide. It gradually turns to an off-white color, however.

Nickel-copper sulfate reaction: A piece of nickel from a spark plug ground electrode is placed in moderately concentrated copper(II) sulfate solution. No immediate reaction is observed.

Nickel-copper chloride reaction: Just like above, nickel only reacts very very slowly with copper(II) chloride solution, hot or cold, concentrated or dilute.

Copper dissolution: A large amount of copper wire pieces were placed in 2:1 3% hydrogen peroxide and hydrochloric acid. Dissolution begins immediately. The smelly solution is placed outside.

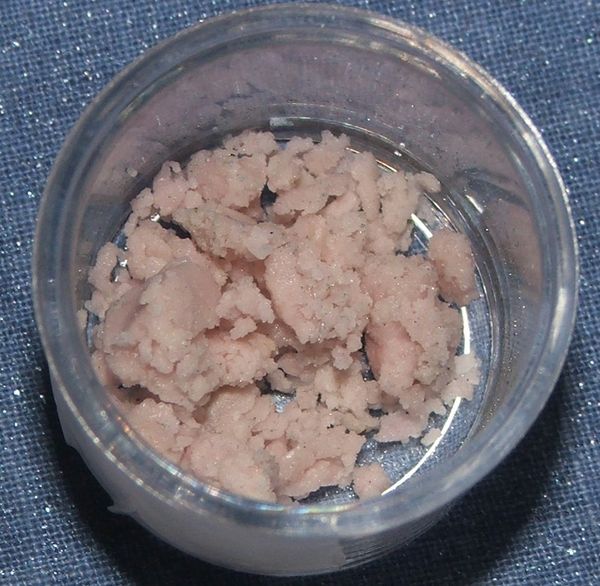

Indium-copper sulfate reaction: Indium reacts rapidly with copper sulfate, decolorizing the solution and precipitating copper. Unlike aluminium, no difference between the reactions In + CuSO4 and In + CuCl2 is discernible. The resulting almost-colorless solution was reacted with ammonia. The formation of a light blue precipitate showed that a significant amount of copper remained and many ammonia washings will be necessary, possibly even a re-dissolution and precipitation, to get pure white indium hydroxide. It is also a light and slow-settling precipitate, making the process slower than it was with bismuth hydroxide in the past. The resulting indium hydroxide is still slightly blue, showing that the last traces of copper are difficult to remove. If I ever do this again I will use hydrochloric acid instead.

Mischmetal burn: Mischmetal shavings burn with a sparkling flame. When glowing mischmetal embers are spit upon, they erupt in a manner similar to magnesium.

Pepto-Bismol reduction: Hydrochloric acid is diluted 5 to 1 and a few drops of Pepto-Bismol paste are placed in the solution. They turn white and the bismuth goes into solution. The solution is filtered and a piece of zinc is placed in it. A thin smear of bismuth metal forms on the surface of the zinc (picture). This is definitely a horrible way to obtain bismuth metal.

Silver dissolution with tracer: The residue of silver wire from the previous silver acetate production is placed in more hydrogen peroxide and acetic acid, with small amount of sodium chloride added as a tracer. The silver residue appears to be catalytically decomposing the hydrogen peroxide without forming any significant amount of silver acetate, as no murky streams are seem coming from the silver.

Indium hydroxide production: It is finished today (see above).

Copper(II) chloride formation: The copper dissolving solution is quite dark, and turns turbid when water is added, showing that some copper(I) chloride is also dissolved from comproportionation. I will have to just let it evaporate and reap the huge harvest of crystals.

Nickel dissolution: Nickel does not seem to be dissolving in acetic acid – hydrogen peroxide mixture. The passivation layer is really strong, on the scale of aluminium or higher.

Copper(II) chloride production: The resulting solution contains a significant amount of copper(I) chloride, which is what makes it so dark. I noticed that a white precipitate was collecting at the bottom of the container, as well as whitish substances on the top. To confirm my fears, I added hydrogen peroxide. A precipitate of copper(II) hydroxide chloride formed, turning the solution blue, and catalytic decomposition of the hydrogen peroxide commenced. All of the added hydrochloric acid was consumed in the formation of the coordination complex with copper(I)/copper(II), leaving none to dissolve the copper(II) oxychloride. I added more HCl to make a nice bluish solution, pretty much clear except for dust (I hate open top evaporation for that reason).

Indium hydroxide production: I took the small but reasonable amount of dried indium hydroxide and placed it on a piece of indium metal for photography, just for fun. The indium hydroxide has a very light blue tinge from residual copper; the dried and hydrolyzed copper(II) carbonate hydroxide mixture is less bluish than the ammine solution that was mixed with the precipitate in aqueous ammonia solution. Therefore, it hardly appears blue in this picture. The indium hydroxide is then placed in acetic acid. It appears to partially dissolve. However, no longer gelatinous to any degree, most of it settles on the bottom. IIRC, aluminium hydroxide dissolved in acetic acid when freshly precipitated. When it was evaporated, it left a crystalline mass that was wet and smelled very strongly of acetic acid, probably some form of basic aluminium acetate. Indium hydroxide probably behaves similarly, dissolving completely after an extended period of time.

Zinc reduction: Zinc is often the metal used to reduce other substances. However, magnesium is a strong enough reducing agent to reduce zinc. I dissolved some zinc acetate in water, forming a clear solution. (The zinc acetate was made 2 years ago by cutting up scratched up pennies and dissolving then very slowly in a yogurt cup of vinegar. Then a fan was blown on the solution to dry it. It took very long to dry. One day I knocked the solution over and about 80% of it spilled on the floor. I forgot about the 20% remainder and was surprised to see a mass of soft, damp crystals forming in the container a couple weeks later. I canned them and never had a use for such boring compounds as zinc compounds are until recently.) I then decided to go whole hog and chucked the entire end of my magnesium fire-starter into the solution. It began bubbling gently. After 12 hours, it was covered with bluish-gray zinc powder, some of which had fallen off to the bottom of the solution. After 24 more hours, the zinc had turned white from surface aerial oxidation.

Mischmetal oxidation: Mischmetal reacts with warm water to form a dark grayish film of metal hydroxides, along with hydrogen gas.

Lead-copper(II) chloride reaction: Lead reacts with concentrated copper(II) chloride solution to form, initially, a dark green mixed oxidation state copper complex. This is because only a small amount of copper was formed before the insoluble lead(II) chloride began forming a protective layer over the lead metal. The copper then dissolved in the excess copper(II) chloride. When the copper complex (which hydrolyzed to white copper(I) chloride and green copper(II) chloride when diluted with water) was washed away, an area of lead(II) chloride remained.

[redacted]

Vacuum tube getter: This getter could be either barium or caesium. However, it seems to be barium because 1) it does not react instantly with air – it takes a few seconds – and 2) its reaction with water is not instant either. The top picture shows the white coloration after the getter is exposed to air, as well as the basic pH of the white substance when damp. The left picture shows the mirror-like getter on the top end of the last remaining vacuum tube. Its golden color made me think that it was caesium, but barium could be a more realistic guess. Wikipedia says that barium is the most common getter material, so it is likely barium.

[redacted]

Copper(II) chloride dehydration: I heated the copper(II) chloride crystals in a test tube. They appeared to melt, but quickly solidified to a brown solid while releasing a mixture of HCl and water vapor. The remainder was a bland brown solid quite different from the dihydrate. When water is added, heat is released and a green substance is formed, which appears to be an insoluble basic copper chloride due to overheating of the test tube. The hydration is videotaped.

Nickel(II) chloride reduction: Nickel is dissolved in a mixture of hydrogen peroxide and hydrochloric acid. It is then neutralized with baking soda and the precipitate redissolved, making the solution only slightly acidic. After being split into three parts, three metals were added: magnesium, zinc, and iron. Based on magnetism, no precipitate of nickel formed in any container, showing that no divalent nickel was reduced at these concentrations.

Copper(II) oxide dissolution: After copper(II) oxide is calcined it is insoluble in 5% acetic acid, forming no coloration when mixed.

[redacted]

[redacted]

Lithium and oil: Lithium appears to react slowly with olive oil, probably because of impurities in the oil. But cooking oils can be used as a temporary storage medium for lithium metal. Here is the lithium in the oil, as well as the original lithium from the battery.

Cobalt(II) hydroxide: I reacted lithium with water to form a warm solution of concentrated lithium hydroxide. When cobalt(II) chloride crystals were added, they became coated with a layer of blue cobalt(II) hydroxide which turned red very quickly in the elevated temperature from the lithium-water reaction.

Triiodide disproportionation: The decoloration of tincture of iodine occurs very quickly when lithium is placed in it.

Lithium – mischmetal: Lithium mixed loosely with mischmetal shavings does not easily ignite, showing that increased reactivity in the alkali metals as compared to the alkaline earth metals and lanthanides does not mean increased flammability.